Post-harvest processing plays a critical role in the agricultural supply chain, directly influencing the efficiency of food preservation and the reduction of waste. The importance of effective post-harvest processing can be outlined across several key aspects:

- Quality Preservation: Post-harvest processes like cleaning, sorting, grading, and packaging help maintain and even enhance the quality of agricultural products. These steps are essential for ensuring that the food that reaches consumers is safe, clean, and of high quality.

- Reduction of Losses: A significant amount of agricultural produce is lost between the time of harvest and consumption due to spoilage, pests, and mishandling. Effective post-harvest techniques, such as controlled atmosphere storage, refrigeration, and chemical treatments, can significantly reduce these losses.

- Extending Shelf-life: Techniques like drying, canning, and freezing extend the shelf life of produce, making it possible to consume it long after it has been harvested. This not only helps in stabilizing food prices but also ensures food availability during off-seasons.

- Value Addition: Post-harvest processing allows for the transformation of raw agricultural products into forms that are more valuable and convenient. For example, turning fresh fruit into jams, juices, or dried fruit increases its value, enhances its market appeal, and extends its marketable life.

- Economic Benefits: By reducing losses, adding value, and extending shelf-life, effective post-harvest processing contributes to higher profits for farmers and distributors. It also creates jobs in processing, logistics, and marketing sectors.

- Food Safety: Proper post-harvest treatment helps in reducing the risk of foodborne illnesses by eliminating pathogens and pests from food products. Techniques such as proper washing, thermal processing, and chemical treatments are vital in ensuring food safety.

- Sustainability: Reducing food waste through efficient post-harvest processes is crucial for sustainability. It helps in conserving resources such as water and energy used in the production, harvest, and transportation of wasted food. Moreover, improved processes can decrease the environmental impact associated with decomposing waste that produces greenhouse gases.

Enhancing Post-Harvest Processing with Solar Dryers

Solar thermal energy is a technology that harnesses the sun’s heat to power various applications, from residential heating to industrial processes. Unlike photovoltaic systems that convert light directly into electricity, solar thermal systems absorb sunlight and convert it into thermal energy. This heat can then be used directly or stored for use when sunlight is not available, making it an excellent solution for applications like solar drying in agricultural settings.

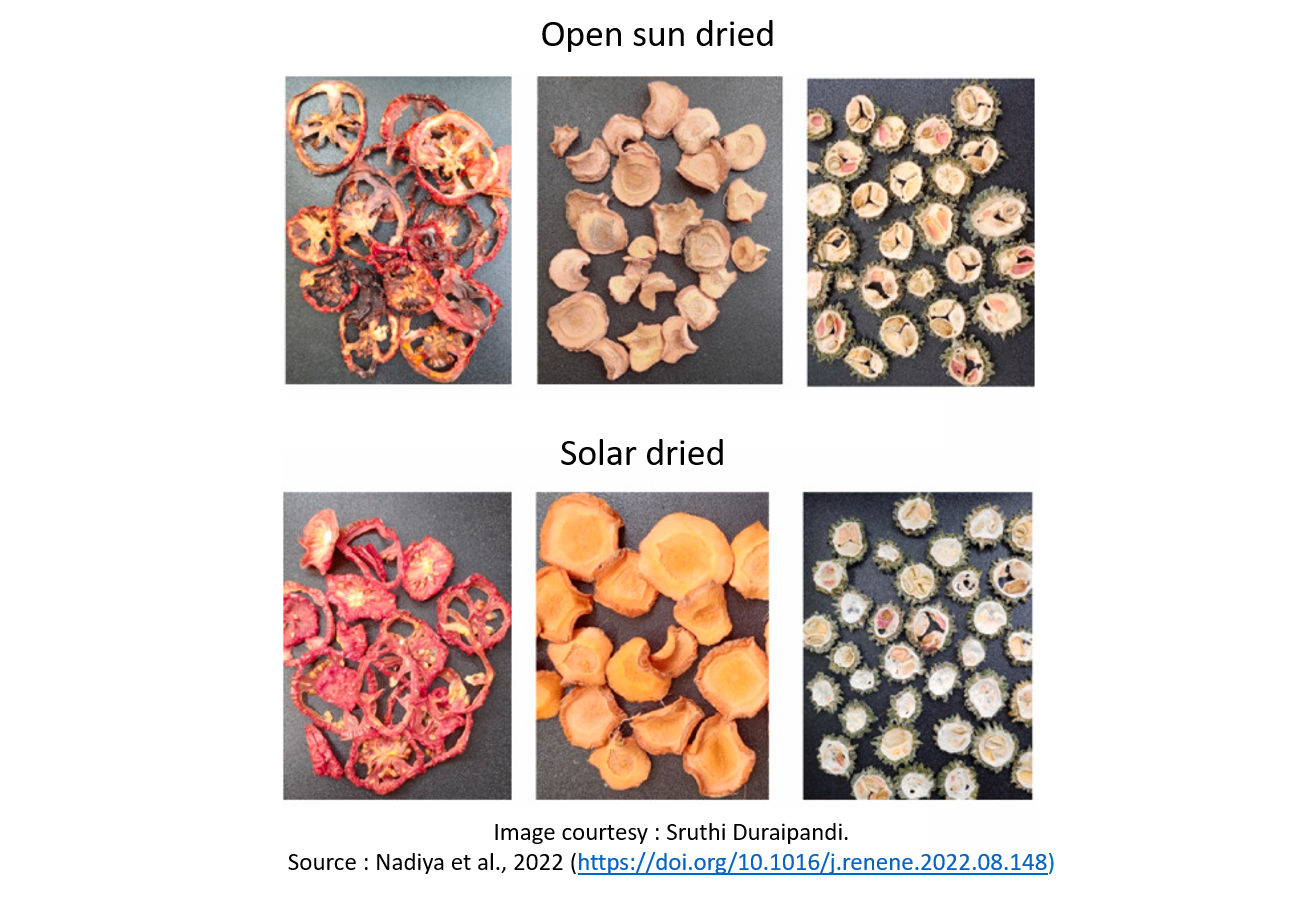

Solar dryers play a pivotal role in post-harvest processing by using solar heat to reduce moisture in perishable goods, which inhibits spoilage and extends shelf life. However, their dependence on sunlight has traditionally limited their use. Integrating PCMs addresses this limitation by storing excess solar energy and releasing it gradually, ensuring consistent drying temperatures throughout the day and night.

The Role of Phase Change Materials in Enhancing Solar Dryers

Integrating Phase Change Materials (PCMs) into solar dryers introduces a groundbreaking advancement in the efficiency of post-harvest processing. PCMs can store excessive solar energy during peak sunlight hours and gradually release it, maintaining consistent temperatures within the dryer. This technology ensures that solar dryers can operate beyond daylight hours, significantly enhancing their usability and efficiency.

Breakthrough with Palmitic and Sebacic Acids

Recent research from the Solar Thermal Energy Laboratory (STEL) headed by Dr. A Sreekumar, from Department of Green Energy Technology, Pondicherry University, showcased in the Journal of Energy Storage introduces a PCM formulated from an 80:20 molar ratio of palmitic to sebacic acid (Sruthi Duraipandi et. al., 2024). Selected for its suitable melting point and high latent heat capacity, this eutectic mixture optimizes the energy storage capacity of solar dryers, thus enhancing their utility in post-harvest processing.

Key Research Insights

- Thermal Efficiency: The selected PCM shows exceptional thermal retention, functioning effectively even after 1000 cycles of melting and solidifying. This property is crucial for its long-term application in solar drying systems (Sruthi Duraipandi et. al., 2024).

- Enhanced Dryer Performance: The integration of this PCM not only extends operational hours but also stabilizes the internal environment of the solar dryers. This stability is vital for achieving uniform and efficient drying processes.

Enhancing Solar Dryers with PCM Technology

- Energy Cost Reduction: PCM-integrated solar dryers harness solar energy more efficiently, significantly cutting down the need for supplemental energy sources, which helps in reducing operational costs and environmental impact.

- Quality Preservation: By maintaining consistent internal temperatures, these enhanced dryers prevent the potential overheating or rapid drying that can degrade the quality of agricultural products, ensuring that they retain their nutritional value.

- Operational Flexibility: Enhanced solar dryers can function effectively under variable weather conditions, making them a reliable solution for post-harvest processing. This capability is instrumental in minimizing the risk of food wastage due to unpredictable climate patterns.

Integrating Phase Change Materials for Enhanced Performance

Solar thermal energy is increasingly recognized as a sustainable and efficient energy source for agricultural post-harvest processing, particularly in drying operations. Solar dryers, which harness solar energy to reduce moisture in perishable goods, play a crucial role in extending the shelf life of these products and preventing spoilage. However, the effectiveness of solar dryers is often limited by their reliance on direct sunlight, confining their operation to daylight hours.

To overcome this limitation, recent advancements in Phase Change Materials (PCMs) offer a promising solution. A novel study focusing on a binary eutectic mixture of stearyl alcohol and benzamide (SA-B) demonstrates the potential of these materials to enhance the thermal performance of solar dryers significantly. This PCM not only possesses a suitable melting point of 54.26°C but also exhibits a high latent heat capacity of 157.45 kJ/kg, making it ideal for maintaining consistent drying temperatures even after sunset (Sruthi Duraipandi et. al., 2023).

Thermophysical Properties and Solar Dryer Integration

The study, conducted at the Solar Thermal Energy Laboratory of Pondicherry University, provides a comprehensive analysis of the PCM’s thermophysical properties. The SA-B mixture was tested for its melting point, thermal stability, and compatibility with solar dryer components, particularly concerning corrosion resistance with materials like stainless steel.

The integration of 5 kg of this eutectic PCM into a solar dryer extended the drying operation by over 4 hours, enhancing the dryer’s efficiency on intermittent solar days and evenings. This extension is crucial for maintaining continuous drying processes, which is vital for preventing the rapid deterioration of harvested crops (Sruthi Duraipandi et. al., 2023).

Future Research and Applications

While the current study highlights the effectiveness of the SA-B eutectic PCM in a lab-scale setup, further research is needed to scale this technology for commercial use. Future studies should focus on optimizing the composition and loading of PCMs in solar dryers to maximize thermal performance and cost-efficiency. Additionally, integrating advanced monitoring technologies could further enhance the control and efficiency of PCM-enhanced solar dryers.

The integration of advanced PCMs like the stearyl alcohol and benzamide mixture into solar drying systems marks a significant step forward in post-harvest processing. This technology not only aids in avoiding wastage by improving the efficiency of drying processes but also supports sustainability by reducing the reliance on non-renewable energy sources. As these technologies continue to evolve, their potential to improve food preservation while minimizing environmental impact offers a promising outlook for the future of agricultural processing.